In today’s highly competitive business climate, just about every manufacturer is looking for ways to reduce operating costs. Factors such as increased environmental regulations and cheaper overseas labor make it more challenging than ever for manufacturers to turn a profit. Great Lakes Metal Finishing is a U.S metal plating manufacturer that produces comprehensive zinc and zinc-nickel coatings for all industrial, automotive, and manufacturing industries.

A U.S. Zinc Plating Manufacturer for the Automotive Industry

Some companies believe they will save money by manufacturing products in other countries; however, most end up paying the price for it when it comes to shipping the products they make back into the U.S. Great Lakes Metal Finishing supplies zinc and zinc-nickel platings in the U.S., cutting down on the shipping costs associated with bringing products across borders and eliminating oversea shipping costs. Companies like GLMF facilitate all of their manufacturing in the U.S. They’re able to provide America with more than just superior products; they also provide American workers with jobs.

Three Reasons Why Zinc Plating is the Top Cost-Effective Finishing Method

As manufacturers look for cost-effective finishing methods for products, zinc electroplating deserves strong consideration. While zinc electroplating may be seen as an additional business expense, its benefits can actually lower your production costs and contribute to a better, longer-lasting life cycle. Zinc electroplating can:

- Lower Material Costs & Enhance Appearances

- Improve Product Quality

- Improve Functionality & Reduce Coating Costs

Improve Product Quality

By using zinc electroplating, a products’ strength, durability, and corrosion resistance are enhanced, thus improving their overall quality and longevity. Frequently, zinc is alloyed with other metals, which can result in improved performance when compared to plating with zinc alone. A zinc-nickel alloy, which can consist of a nickel component of anywhere from 6% to 20%, can dramatically increase corrosion protection. Products that have been electroplated using zinc or zinc-nickel will not have to be replaced as frequently and will experience fewer customer returns due to inferior quality or performance.

Lower Material Costs & Enhance Appearances

Manufacturing companies are up against spiraling material costs, which pose one of the biggest threats to making a profit. Zinc and zinc-nickel electroplating enable an increase in the product’s surface thickness without having to use extra materials. This can result in a significant reduction in material costs over time. If manufacturers are relying on aesthetic appeal, electroplating can prove to be a cost-effective and aesthetically pleasing option. For instance, a surface with a thin layer of olive drab zinc coating is much more affordable than making the entire product from zinc.

Improve Functionality & Reduce Coating Costs

Zinc electroplating can provide a low-cost method for increasing the functionality of a product while reducing coating costs. For example, if you manufacture electronic components, zinc or zinc-nickel are both extremely inexpensive metals and can achieve your objective much more affordably than plating with other methods. If you paint your products, clear zinc plating can deposit a base coat that promotes the adhesion of the paint or top coating. You’ll be able to create the desired surface finish without having to apply multiple coating layers, which is another reliable way to lower your material costs.

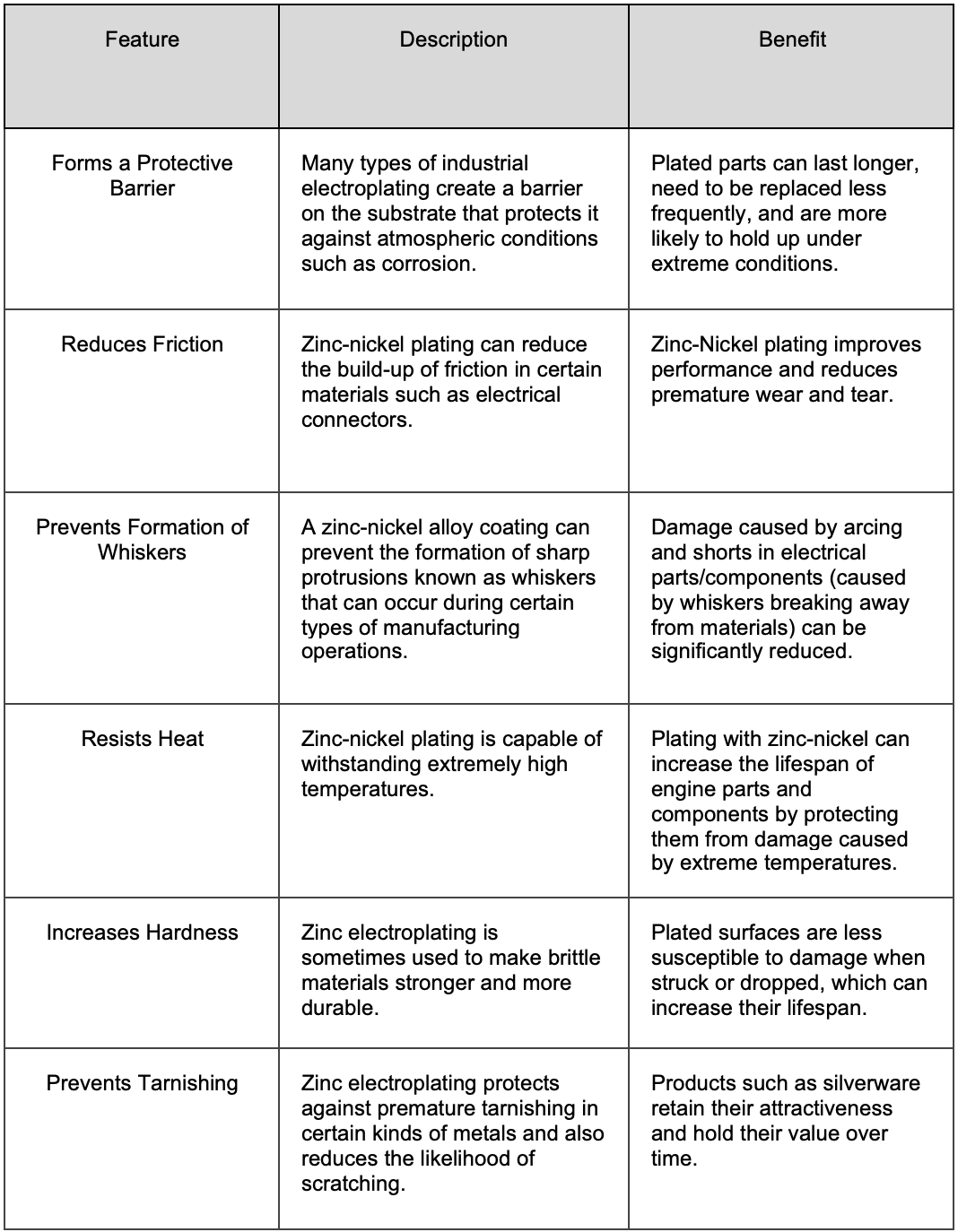

Additional Features & Benefits of Zinc Electroplating